RB 3000

Rubber Rebound Resilience Tester

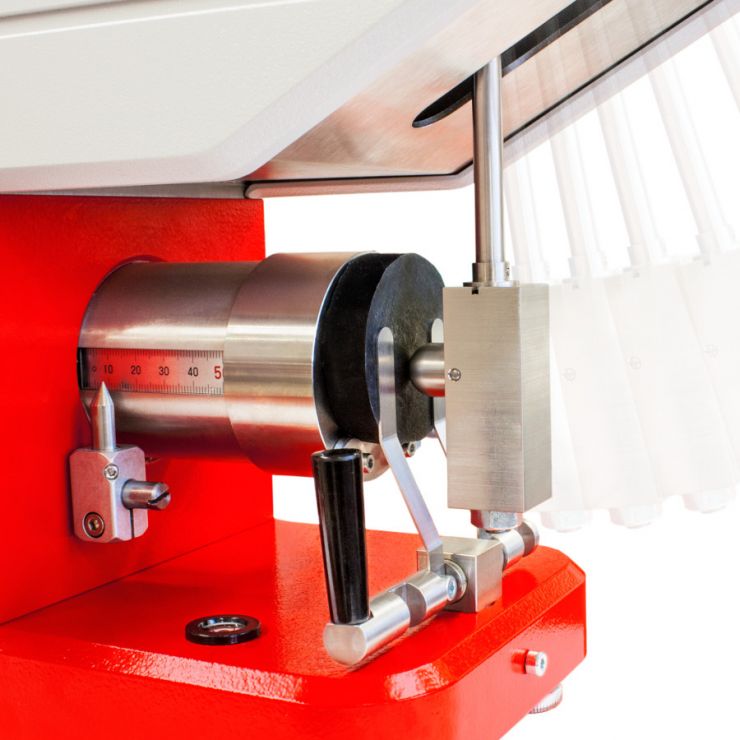

Automated rubber rebound resilience tester for accurate determination of resilience properties of rubber compounds

Essential to R&D or quality control, the RB 3000 rubber rebound resilience tester determines the resilience and shock absorption properties of rubber and elastomeric materials. Utilizing a multi-language 5” touch screen display, the RB 3000 effortlessly guides users through each testing sequence. The pendulum mechanism features a 15mm diameter hammer fin connected to an air bearing system. The bearing system is then connected to a high resolution non-contact encoder guaranteeing the highest precision in pendulum angle measurement.

RB 3000 Features

- Simplified touchscreen operation

- Automatic detection of incorrectly placed samples

- Fully automated test sequence with motorized pendulum release and return

- Integrated calibration routines allow users to measure, calibrate, and compensate the pendulum friction

- Interchangeable hammers, fins and anvil plates for various applications and sample types

- Three available temperature control systems allow for testing at elevated or even sub-ambient temperatures

- Easy setup with leveling feet, and an integrated spirit level

- Heavy duty vibration resistant machine frame

- Test sequences include up to three pre-test or full test hits

- Results displayed on the 7" touchscreen and / or delivered to a database

Technical Specifications

Standards | ISO 4662 |

Measurement Method | Pendulum rebound resilience measurement (Schob type) |

Test Modes | Single, Median of 3 tests (with 3 or 4 conditioning hits) |

Operation | Fully automated with automatic pendulum lift and release |

User Interface | Integrated 5” color - Touchscreen |

Sample Dimensions | Cured rubber buttons or sheets with 0 to 30mm thickness |

Anvil Distance | 0 to 60mm (steplessly adjustable) |

Release Angle | 90° |

Resolution / Accuracy | 0.001° arc / 0.1% Rebound Resilience |

Hammer fin | hemispherical, 15mm in diameter |

Impact Velocity | 1.98m/s |

Impact Energy | 426.5 kJ/m3 |

Pendulum Capacity | 0.5 Joule |

Pendulum Length | 7.87 in (200 mm) |

Pendulum Mass | 255g |

Output Languages | English, French, German, Spanish, Russian (others on request) |

Output Interfaces | Serial (RS232) and USB 2.0 |

Data Acquisition | MonLink software (optional) for test configuration management, data acquisition and statistical evaluation |

Electrical | 90 - 250 V , 1 Amp, 47-63 Hz, Single phase |

Weight | Approximately 50 kG net |

Dimensions (H x W x D) | 14.57 in x 22.83 in x 7.09 in (370 mm x 580 mm x 180 mm) |

Options |

|

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified