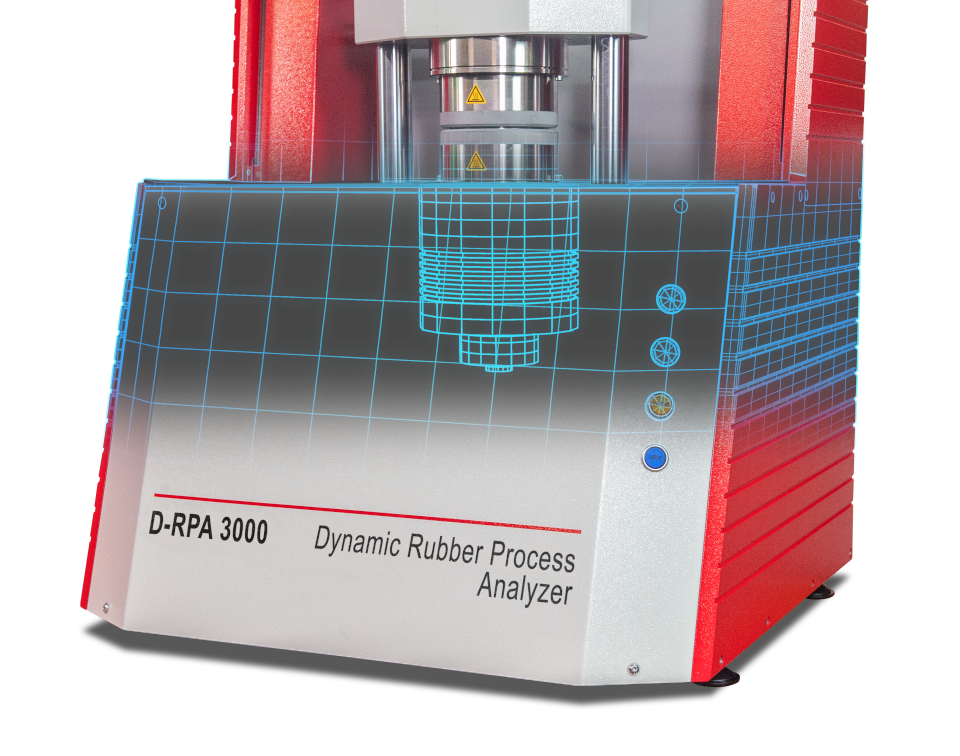

D-RPA 3000

Dynamic Rubber Process Analyzer

The MonTech Rubber Process Analyzer (RPA) is the most advanced dynamic rubber rheometer for attaining key data on rubber and polymer molecular properties.

Manufactured with the latest advancements in rubber rheological technology, the MonTech rubber process analyzer assists mixers and rubber product manufacturers in taking back control of their materials. The RPA reveals key properties for problem solving including the analysis of raw elastomer or compound molecular properties. Additionally, the RPA will aid in the discovery of processing indicators, vulcanized dynamic performance, process simulations and much more. Where traditional rubber rheology cannot detect challenges or material differences, the RPA finds them, identifies them, and gives users more control on how to use their rubber materials. Whether located in high-end R&D laboratories, production laboratories, or the mixing floor, the MonTech RPA is built for long-term accuracy and reliability.

More choose MonTech around the world for the latest advancements in rubber rheology, and service you can count on.

Motor Matters

The heart of the Rubber Process Analyzer is its motor. Where others started, we have advanced the technology forward. Our patented Direct Drive Motor, designed exclusively for RPA applications, enables the largest dynamic range of any RPA. Featuring low friction ceramic bearings, an unbeatable data resolution, and a high-torque gearless actuator, our motor proudly stands out as the best with zero failures globally. Choosing the MonTech RPA means choosing the right motor for long term accuracy and reliability.

- Oscillatory Strain: 0.0001 – 360 ° Arc

- Oscillatory Frequency: 0.001 – 100 Hz

- Optional: Rotations Per Minute 0.01 – 900 RPM

Load. Test. Remove. Repeat.

Automation should make your life easier, not harder. Production laboratories with high testing throughput depend on reliable automation to match the number tests to accomplish. Engineered robotics, or linear film feeding, guide the sample with ease onto the die cavity where testing may commence.

Automation Types:

- Tray Autoloader: 24, 48 or 100 samples per tray

- Linear Autoloader: 5 or 10 sample linear feeding

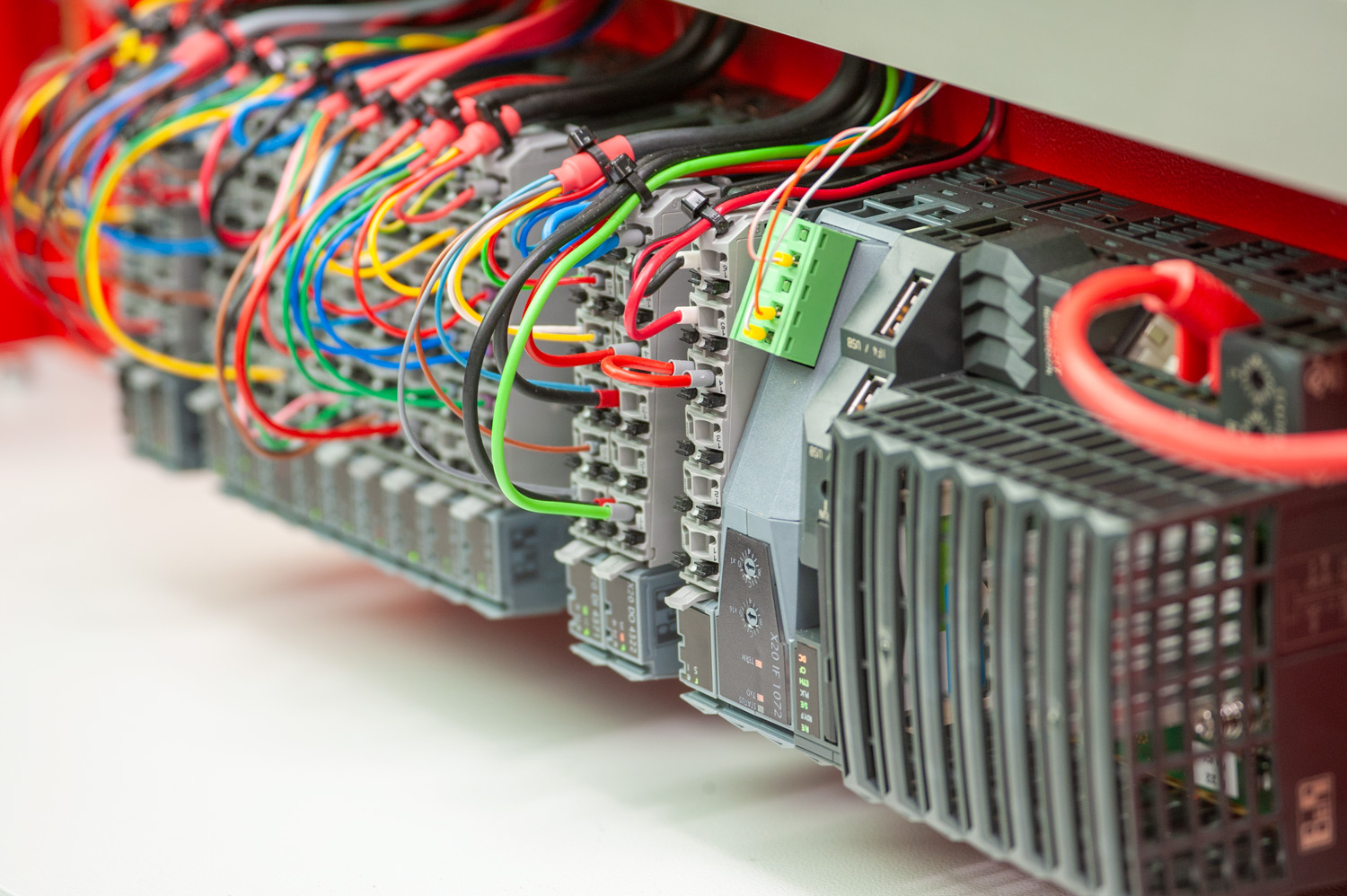

Industrial Electronics That Endure. Controls That Deliver.

The leaders in rubber product manufacturing demand the highest standard in industrial electronics. Whether on the mixing line or operating in a QC or R&D laboratory, directing the operation of the RPA, is its PLC. Designed by one of the top three European producers of industrial PLCs, the RPA’s PLC is considered an industrial standard across high-tech industries and advanced automation applications. It’s fully digital with no analogue signal processing. If something goes wrong, the modular concept enables quick replacements if necessary and is available for remote diagnostics.

Frames Engineered

for Accuracy

The machine frame plays a major role in the long-term accuracy and stability of RPA data. Each MonTech RPA frame is built from aerospace grade aluminum and stainless steel including an 80 mm thick baseplate, 50mm pullrods, an 80 mm crosshead and 20mm thick side panels. This results in a superior frame stiffness which significantly improves repeatability, correlation, reduces damping abilities in high-frequency tests, all the while reducing the signal-to-noise ratio.

Fan-less Design: The frame’s design mitigates any form of potential heat build-up in the electronics cabinet. With no need for fans, and the frame’s sealed housing, carbon black contaminated electronic failures are a challenge of the past.

Technical Specifications

Die Configuration | Biconical, closed die system, sealed |

Die Gap | 0.45 mm nominal, variable die gap and closing force optional |

Sample Volume | approx. 4.5 cm3 |

Drive System | Direct, wearless servo drive system with ceramic bearings |

Oscillation Frequency | 0.001 Hz to 100 Hz (0.05 to 6000 cpm) |

Oscillation Strain | +/- 0.0001° to 360° (+/-0.0014% to 5032%) |

Torque Range | 0.0001 to 250 dNm |

Normal Force / Pressure (opt.) | 0 to 10.000 kPa (1.450 lbin), Auto tare |

Temperature Control System | Ambient to 232°C, precision +/-0.03°C |

Measured Data | Torque (dNm, lbf.in, kgf.cm), Temperature (°C, °F), Pressure (bar, kg per cm²), Time (min - min / min - sec / sec), Shear rate (1/s, rad/s), Cure rate (1/min, 1/sec) |

Calculated Data | S΄, S˝, S*, G΄, G˝, G*, tan δ, η΄, η˝ and η*, J΄, J˝, J* |

Test Programs | Isothermal, non-isothermal, timed, temperature sweep, strain sweep, frequency sweep, shear rate sweep, multi sweep, relaxation, retardation, hysteresis, tension tests, LAOS, steady shear |

Data Interface | Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.) |

Pneumatics | min. 4.5 Bar / 60 psi |

Electrical | 200-240 V, 6 Amps, 47-63 Hz, Single phase |

Dimensions (H x W x D) | 59.84 in x 26.77 in x 23.62 in (152 cm x 68 cm x 60 cm) |

Optional Features

-

Easily improve productivity.

Linear automation systems are ideal for online testing, utilizing a fast and reliable direct conveyor feeder with the lower film as a transportation carrier.

5 or 10 Samples.

Ideal for online automated testing, this system features automated sample loading and unloading with a linear queue of either 5 or 10 test samples at a time.

Linear automation systems are always the preferred choice for very sticky materials such as silicones or glue that sample loading arm systems might not be able to handle.

Maximum Efficiency

Tray automation systems allow users to queue larger amounts of samples and leave the testing system running totally unattended over long periods. With MonTech's patented direct sample hadling system, sample placement accuracy and test result repeatability is significantly increased. Samples are handled and monitored by a high-volume vacuum system, ensuring perfect sample pickup, transporation and drop-off - even for less than ideal test samples.

24, 48, or 100 Samples Tray

This system features automated sample loading and unloading with a direct tray-to-chamber handling system.

-

- Designed for calibrating MDR Torque

- Certificate of ISO/IEC17025 Accredited Calibration Included

MDR torque measurements are performed by a high-resolution DMS strain gage sensor inside the machine which should be calibrated at regular intervals. The MDR Torque Calibration Standard is specifically designed to accurately calibrate this strain gage sensor with a high degree of precision. The concave surfaces of the standard are precision-machined to fit the bi-conical dies of the MDR. This design allows the standard to be self-seating – minimizing cosine error and ensuring accurate and precise calibration.

-

The system includes a combined force / torque transducer and a 2-channel amplifier system for real-time simultaneous measurements of torque and force. This system measures the normal force to calculate pressure within the rheometer's die cavity. The force transducer and amplifier are balanced automatically before each test. Measuring the pressure and torque simultaneously is an easy way to quantify the expansion/contraction of the compound before, during, and after vulcanization.

-

The advanced cooling system features a liquid cooling system with an external chiller unit. The cooling system works as an addition to the pneumatic cooling system. If lower temperatures are required, the chiller unit will begin cooling down the dies to as low as -40°C. Both dies are separately chilled and cooled by the external unit connected to the instrument. The liquid cooling system is able to run anything from sample curing down to glass transition testing.

The heating system of the dies remains unchanged; instruments equipped with this chiller unit maintain the functions of a Moving Die Rheometer or Rubber Process Analyzer.

This technology is patented worldwide by MonTech

-

Integrated cartridge cooling system that separates the provided air streams into cold (-45°C) and hot (+110°C) fraction to enhance the performance of the machine compared to the standard pneumatic cooling system. This system is especially suitable for testing at or below room temperature in order to provide the most accurate test results as well as correlations with final product application environments. This system is highly recommended for dynamic testing and a must for testing in the ambient temperature range.

The vortex tubes are installed in line with the standard pneumatic cooling system.

The operation principle of the MCool 10 cooling system is very simple:

This technology is patented worldwide by MonTech.

-

This is a 5.7” QVGA Color LC Touch ScreenDisplay with 10 Touch-Keys, Protections Class IP65 mounted into a rugged holder on the right side of the instrument. Enables quick views into:

- Main Screen: Set-Values and Test Progress

- Configuration: Test Parameters (Time, Temperature, Frequency, Angle, etc.)

- Calculated Test Results with fixed data points

- Calibration

- Service Functions

- Information: Machine Runtime, Versions, etc.

-

Description: The MonControl Data Management Client is a centralized lab management software (windows based) allowing management of all laboratory data generated by MonTech testing instruments and externally connected by third party devices. In addition, manual entry or import of date from simple serial devices is seamlessly possible and is based on the proven MonControl Database SQL structure.

- Test Configuration Management: Configure and keep track test configurations, settings, setpoints and tolerance limits.

- Live View: The new Live View will give real-time numerical and graphical information on lab instruments and activities

- Result Table: Used for management of results, compiling additional data and further calculations

- Reporting & SPC: Integrated reports allow advanced generation of reports including result graphs, spreadsheets, XMR, histograms, and other SPC charts on any material. Custom reports may also be added.

- Data Export: Seamless data exports for external reporting in TXT, excel, pdf, word and many other formats

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified