MV 3000 Basic

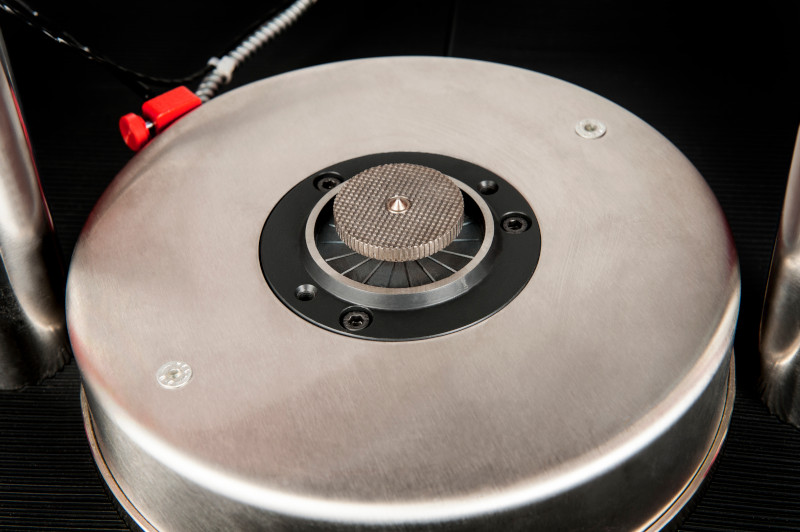

Mooney Viscometer

Entry-level Mooney Viscometer for quick processability checks.

The MonTech MV 3000 Basic Mooney Viscometer delivers accurate and repeatable measurements of Mooney Viscosity, scorch and stress relaxation. Designed for both laboratory and production environments, it ensures consistent quality control and basic characterization of a rubber material’s processability.

MV 3000 Basic Features

- Fanless aerospace grade aluminum and stainless-steel framing

- Brushless, Speed controlled, DC Motor

- Standard two RPM

- Integrated self-diagnostic instrument control software

- Pre-programmed test parameters

- Integrated multi-color LED status bar

- Includes MonControl instrument management software

- Host-system linkable for easy integration into any laboratory

- Lower radial V-Groove die – accommodates large or small serrated rotor

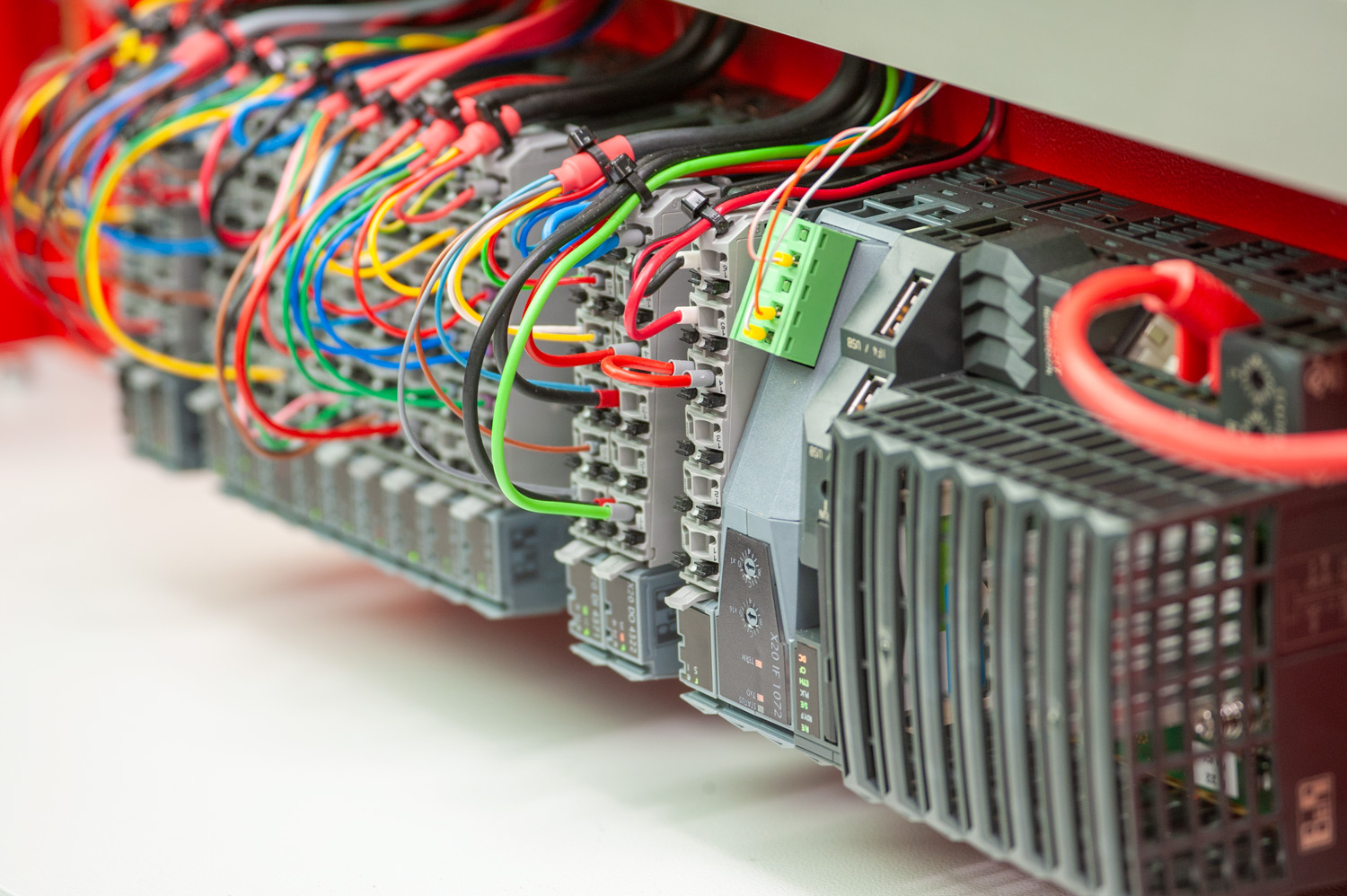

- Equipped with industry standard programmable logic controller

The Mooney Motor That Drives Better

All MonTech Mooney Viscometers come with a brushless, speed controlled, and closed loop DC motor with gearhead. The advanced motor-style creates an unmatched improvement in reliability and creates a lower signal to noise ratio. In turn, the user will see greater data repeatability, an elimination of stepper ripples, and a smoother Mooney curve for the lifetime of the instrument.

- Standard Speed: 2 RPM

Industrial Electronics That Endure.

The leaders in rubber product manufacturing demand the highest standard in industrial electronics. The getCollectionName(); ?>’s PLC controls all functions in the instrument, from operation to data recording. Designed by one of the top three European producers of industrial PLCs, the MDR’s PLC is considered an industrial standard across high-tech industries and advanced automation applications. It’s fully digital with no analogue signal processing. If something goes wrong, its modular design enables quick replacements if necessary and is available for remote diagnostics.

Technical Specifications

Standards | ISO 289:2018 |

Die Configuration / Rotor | According to international standards |

Force Measurement | In-line torque transducer |

Closing Force | 11.5 kN |

Rotor Speed | 2.00 turns per minute (0.21 Radians / second) |

Rotor Shaft Seal | Standard or long life seals available |

Stress Relaxation | According to ISO 289:2018, DIN 53523 Part 4 |

Torque Range | 0.01 to 230 MU |

Sample Volume | Two specimens having a combined volume of 25 cm3 |

Temperature Control System | Ambient to 232 °C, precision +/-0.03°C, digital, microprocessor controlled |

Temperature Check System | Recordings of the temperature gradient on the screen, |

Calibration | Fully automatic by built-in calibration weights, software-guided |

Measured Data | Mooney - value (MU) |

Data Interface | Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.) |

Data Points | Over 3500 data points available, including: |

Pneumatics | min. 4.5 Bar / 60 psi |

Electrical | 100-120 V, 8 Amps or 200-240 V, 5 Amps, 47-63 Hz, Single phase |

Dimensions (H x W x D) | 36.6 in x 19.7 in x 22.8 in (93 cm x 58 cm x 50 cm) |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified