MV 3000 BasicEntry-level Mooney Viscometer |  MV 3000Industry standard Mooney Viscometer |  V-MV 3000High-end Mooney Viscometer with variable rotor speed | |||

|---|---|---|---|---|---|

| Rotor Speed | 2 turns per minute | Variable: 0 to 50 turns per minute 0.01 steps | Variable: 0 to 50 turns per minute 0.01 steps | ||

| Temperature System | Ambient to 232 °C, precision +/- 0.03 °C microprocessor controlled | Ambient to 232 °C, precision +/- 0.03 °C microprocessor controlled | Ambient to 232 °C, precision +/- 0.03 °C microprocessor controlled | ||

| Torque Range | 0.01 to 230 MU | 0.01 to 230 MU | 0.01 to 230 MU | ||

| Closing Force | 11.5 kN | 11.5 kN | 11.5 kN | ||

| Determinable Results | |||||

| Mooney Viscosity | |||||

| Stress Relaxation | |||||

| Mooney Scorch | |||||

| Linear Rotor Speed Variation | |||||

| Stepped Rotor Speed Variation | |||||

| International Standards | |||||

| ISO 289:2005 | |||||

| ASTM D 1646 | |||||

| DIN 53525, part 1 - 4 | |||||

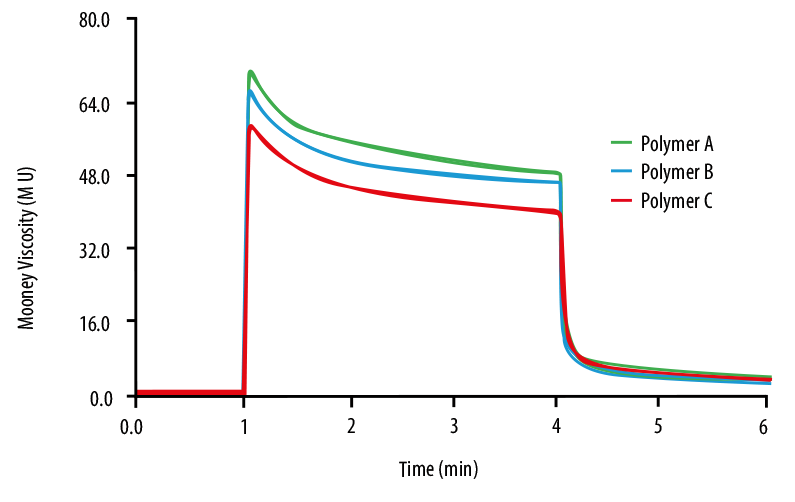

Mooney Viscosity

The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. Defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded and data is automatically calculated at predefined time and viscosity points.

MonTech Mooney Viscometers offer superior precision and repeatability, providing the user with reliable data and making it easy to differentiate between different types and grades of polymers in order to ensure a high processing consistency.

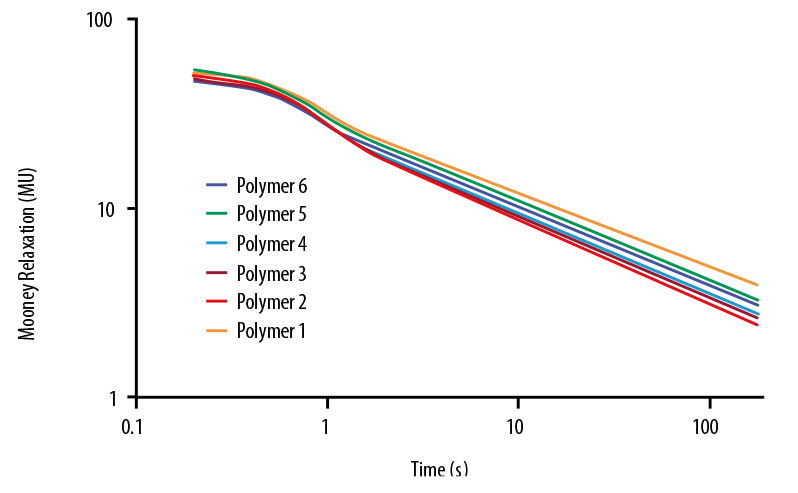

Mooney Stress Relaxation

While Mooney Viscosity testing only provides information about the flow/viscosity of polymers and rubber compounds, stress relaxation testing assesses elastic material behavior.

Once the Mooney Viscosity test is completed, the rotor is stopped within 5 milliseconds and the torque decay is observed and recorded. Once the stress relaxation is completed, the slope-intercept and regression coefficient are calculated, providing excellent correlations in reference to polymer branching and processing.

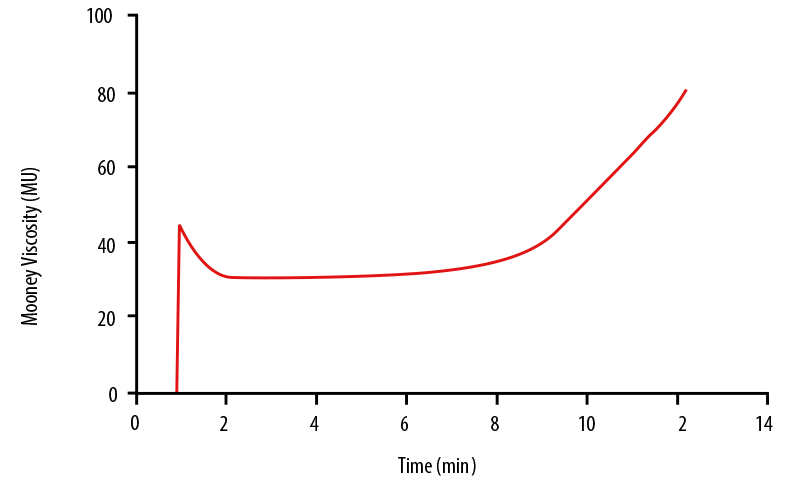

Mooney Scorch

Mooney Scorch tests determine onset of vulcanization (also known as scorching behavior) in rubber compounds. This provides essential data for designing/controlling production processes and verifying material consistency.

Every MonTech Mooney Viscometer offers full Mooney Scorch and Delta Mooney testing capabilities. These capabilities feature a comprehensive selection of data points such as initial Mooney viscosity, minimum viscosity, scorch times and scorch viscosities.

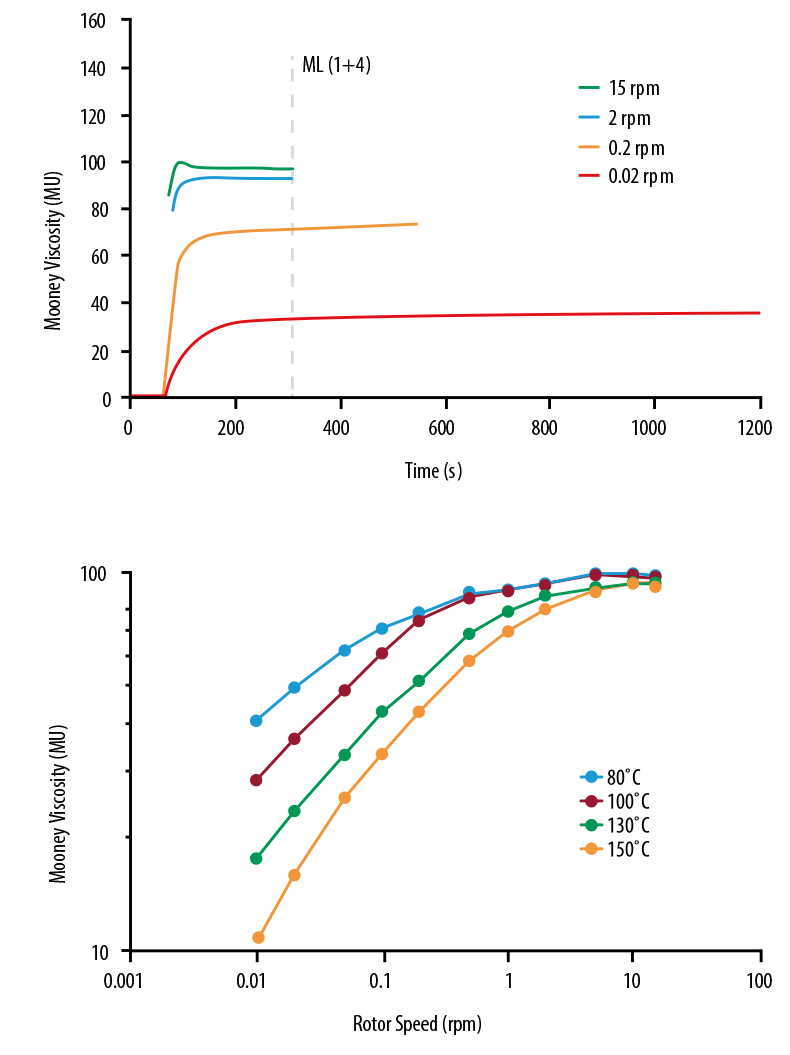

Mooney Viscosity at Shear Rates and Temperatures

MonTech Variable Mooney Viscometers offer full dynamic testing capabilities, allowing measurement of viscosity at variable shear rates and temperatures matching process conditions.

Non-isothermal sequences, variable rotor speed profiles, and step-relaxations can easily be programmed and executed. This allows a detailed and complete understanding of the polymer behavior.

Pneumatic Cooling System

This pneumatic air cooling system cools both dies separately using independent PID-controllers, rapidly cooling the instrument from higher to lower testing temperatures. When using non-Isothermal and RPA operation modes this system enables cooling at any point during the test.

- • Allows test sequences to follow precise cooling ramps and steps

- • Conducts friction heat away from the sample when testing at high shear rates

- • Reduces non-productive time of the instrument and operator by shortening stabilization time

- • Air lines have quick connects at each platen, and exhaust through the platen assemblies

- • Air is supplied by an independent regulator on the back of the machine

Instrument Control Panel

The 5“ Color-Touchscreen allows the machine to be operated from a remote computer or completely standalone for simple quality control testing.