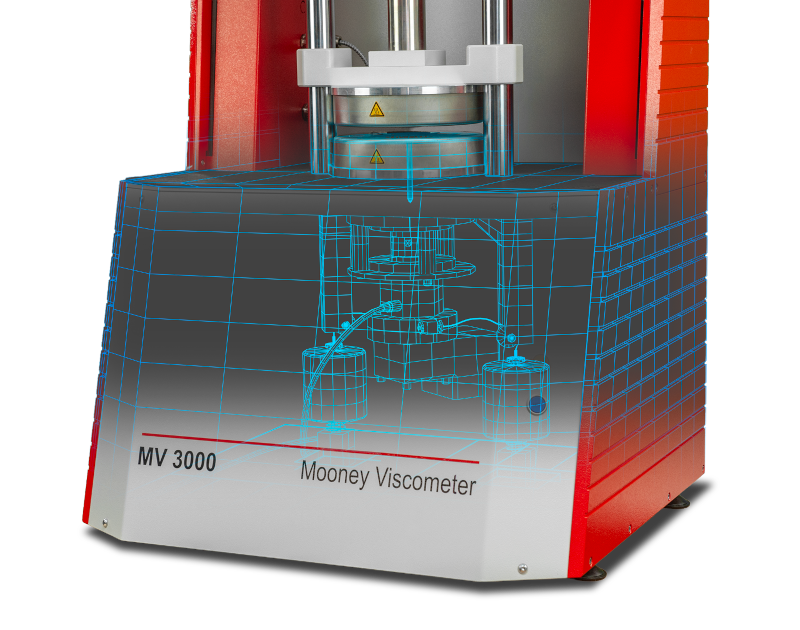

V-MV 3000

Variable Mooney Viscometer

The Dynamic Mooney Viscometer

The V-MV 3000 expands the Mooney Viscometer’s capabilities for testing molecular or processing properties by applying variable shear rates, temperature sweeps, and dynamic test programmability. This is made possible with the implementation of the latest servo drive technology and an advanced heating system, mounted in a high-strength industrial load frame. Designed primarily for R&D centers, the technology allows users to add hundreds of new data points, providing more flexibility in material development.

The Mooney Motor That Drives Better

Traditional Mooney Viscometers operate statically at 2 RPM. For some applications, a higher shear rate well beyond 2RPM is required to discern greater differences in materials or view true molecular characteristics. The V-MVs motor uses state-of-the-art direct servo drive technology. In combination with the smart transducer, the V-MV offers:

- Rotations Per Minute: 0 to 50 RPM, 0.01 steps (0 to 5.25 radians / second).

- Test Time: User Selectable

- Mooney Range: 0.01 – 230 MU (300 Optional)

Mooney Temperature Sweeps

If you have ever wanted to run a temperature sweep on a Mooney Viscometer, it is now possible. It’s as easy as opening the dynamic test menu, select your start temperature, end temperature, rate and rotor speed.

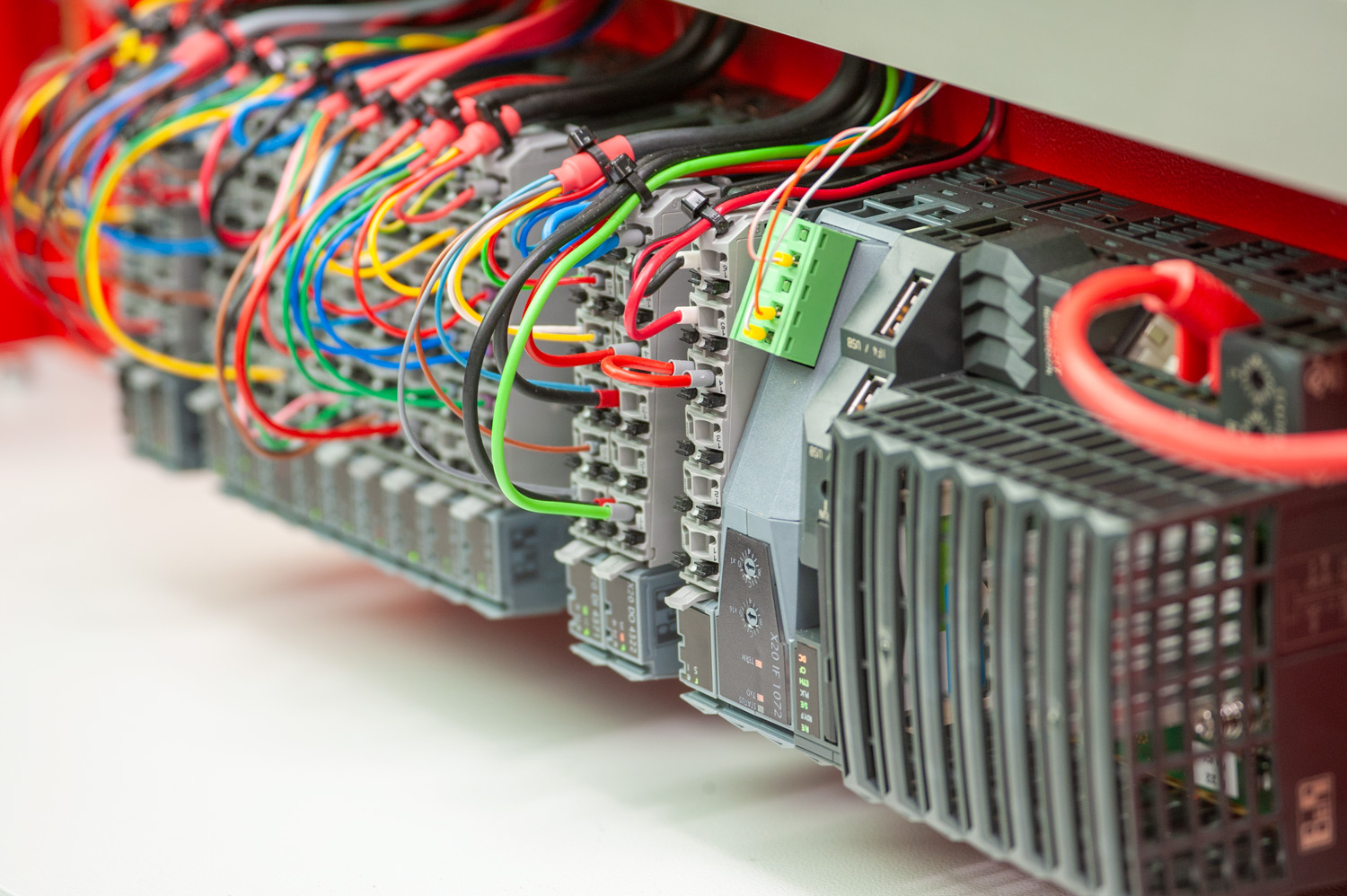

Industrial Electronics That Endure. Controls That Deliver.

The leaders in rubber product manufacturing demand the highest standard in industrial electronics. The V-MV 3000's PLC controls all functions in the instrument, from operation to data recording. Designed by one of the top three European producers of industrial PLCs, the V-MV 3000's PLC is considered an industrial standard across high-tech industries and advanced automation applications. It's fully digital with no analogue signal processing. If something goes wrong, its modular design enables quick replacements if necessary and is available for remote diagnostics.

Frames Engineered

for Accuracy

The V-MV 3000’s frame plays a critical role in the long-term accuracy and stability of the data. The Mooney Viscometer 3000 series frame is built from high-strength aerospace grade aluminum and stainless steel. This includes an 80 mm thick baseplate and 20mm thick side panels. For ultimate parallelism we’ve included 50mm pull rods and an 80 mm crosshead. Together, this results in a superior frame stiffness improving repeatability, correlation, reduces damping challenges in high-frequency tests, all the while reducing the signal-to-noise ratio.

Fan-less Design: The frame’s design mitigates any form of potential heat build-up in the electronics cabinet. With no need for fans, and the frame’s sealed housing, carbon black contaminated electronic failures are a challenge of the past.

Technical Specifications

Standards | ISO 289:2005 |

Die Configuration / Rotor | According to international standards |

Force Measurement | High precision in-line torqe transducer |

Closing Force | 11.5 kN |

Rotor Speed | 0 to 50 turns per minute, 0.01 steps (0 to 5.25 radians / second) |

Stress Relaxation | According to ISO 289:2018, DIN 53523 Part 4 |

Torque Range | 0.01 to 230 MU |

Sample Volume | Two specimens having a combined volume of 25 cm3 |

Temperature Control System | Ambient to 232 °C, precision +/-0.03 °C, digital, |

Temperature Check System | Recordings of the temperature gradient on the screen, |

Calibration | Fully automatic by built-in calibration weights, software-guided |

Measured Data | Mooney - value (MU) |

Data Interface | Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (opt.) |

Data Points | Over 3500 data points available, including: |

Pneumatics | min. 4.5 Bar / 60 psi |

Electrical | 200-240 V, 6 Amps, 47-63 Hz, Single phase |

Dimensions (H x W x D) | 59.84 in x 26.77 in x 23.62 in (152 cm x 68 cm x 60 cm) |

Instrument Options | - Instrument control panel with 5" touchscreen display and printer |

Request a Quote

Experts in Lab Equipment:

The fastest growing rubber testing equipment manufacturer.

13,000 instruments delivered since 1998.

Leaders in Innovation:

Labs evolve.

So should technology in the instruments.

The Team You Can Count On:

Speak to real people who understand your account.

Every time.

Dedicated Support:

Service, software and applications specialists are on standby.

And on your time zone.

Quality Forward:

ISO / IEC 17025 Accredited

ISO 9001:2015 Certified